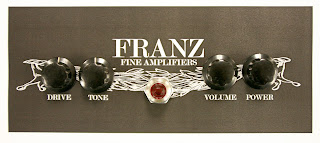

The process for the faceplate etching is complex, and as I was working I decided that I needed to kick the graphic side up a bit. I was inspired by the intaglio printing on a dollar bill and decided to try a vintage scroll type graphic for the art on the amp. Obviously its a breaking from the 1950s look, but who am i kidding? One of my next projects is going to build a tube amp from scratch. This style of graphic really has the right feel for what I have in mind for that project. I’m moving the input jack to the side of the amp for the sake of symmetry, this will also allow me to create another etched brass plate.

This is what the mask looks like, I placed the knobs and lamp for scale. The brass will be etched away in the white areas. The brass will then be primed and painted. Then I’ll sand the surface leaving the paint in the etched areas, a little tarnish and clear coat and it will be done!

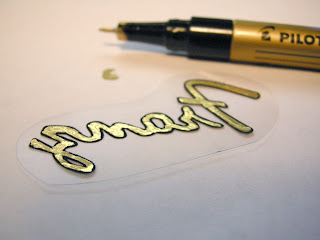

This is the image I developed in photoshop.

I tried a toner transfer last night with no success, with more research I found that you need to use a very specific type of inkjet paper. It was on clearance from staples and will be arriving in a couple of days.