I popped over to pre-engineering to do a little experimentation with the laser cutter and the lace wood sample that I’m going to use on the front of the peoples amp.

The first step was to adjust the mirror assembly to the correct height.

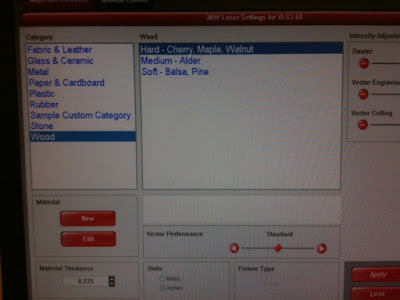

I drafted up three holes to check clearance on pots, switches, and jacks. I also created several lines to test etching line weight. I set up the line weight and vector etching properties in Corel (yuk) The lace wood was .15″ inch thick but it’s fairly dense so I had to use .18″ to get all a clean cut. 51 Grey was about midway on strength and created a well defined etch without flaring up.

I drafted up three holes to check clearance on pots, switches, and jacks. I also created several lines to test etching line weight. I set up the line weight and vector etching properties in Corel (yuk) The lace wood was .15″ inch thick but it’s fairly dense so I had to use .18″ to get all a clean cut. 51 Grey was about midway on strength and created a well defined etch without flaring up. After tweaking settings I found .19″ hardwood to work well with the lace wood.

After tweaking settings I found .19″ hardwood to work well with the lace wood.