I gave a long lab assignment today that kept my students in the zone, I had time to research some old fender advertising from the 50s and 60s. It inspired me to create a registration card for my relic. It sparked an interesting discussion on the role of research in design with my students.

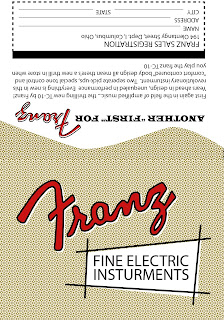

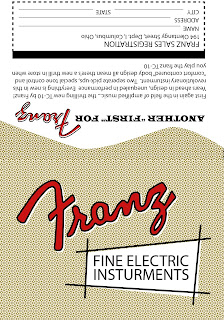

The card is designed to fold in the center, the first image is the exterior and the second is the interior. I used text from several cool old fender advertisements I found at relicdeluxe.com. Here’s what I came up with.

Exterior text:

Another “first” from Franz. First again in the field of amplified music… the thrilling new TC-10 by Franz! Years ahead in design, unequaled in performance. Everything is new in this revolutionary instrument. Two separate pick-ups, special tone control and “comfort contoured” body design all mean there’s a new thrill in store when you play the Franz TC-10.

Interior text:

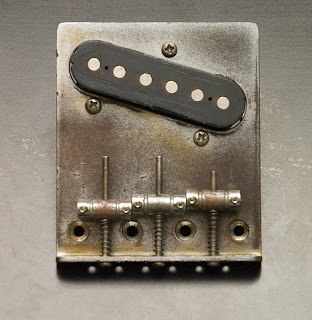

Franz TC-10 Guitar Perfection in a solid body comfort contoured professional guitar providing all of the finest features. Choice hardwood body finished in an array of contemporary colors. Maple neck with rosewood finger board, black pick guard and lustrous chrome metal parts. Two advanced style adjustable pick-ups, one volume and one tone control and a three position instant tone change switch. The adjustable Franz bridge insures perfect intonation and the softest action. The neck has the famous Franz truss rod. The TC-10 is available with or without the Franz built in tremolo. The brand-name Franz represents superior quality. That is why leading musicians prefer Franz fine electric instruments. See the complete Franz line at your leading music dealer and write for the latest catalog of Franz Electric Guitars, Amplifiers, Strings, and Accessories.

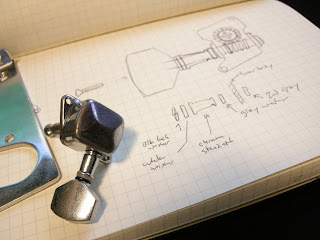

Here’s what I developed, its a work in progress. I’m going to use the exterior halftone pattern on the interior gold panels, I’ll also add images of hardware in the panels.